If you’re thinking about investing in a bespoke vanity unit tailored to your own preferences, you’ve come to the right place. We specialise in building stylish vanity units to our customers’ own unique specifications, with quality and precision at the forefront of our builds.

To provide you with an insight into our business and our processes, here you can find a step by step guide to how your own bespoke vanity unit would be made. Read on to discover the level of detail that goes into creating each of our units and how we make sure to provide the perfect unit to each and every customer.

You choose every aspect of your vanity unit’s design

Each of our bespoke vanity units are designed completely by our customers, whether that’s right here in our workshop, over the phone, or through our online designer to guide you through each stage.

The design process is completely personal to each individual customer – you get to choose the height, length, width, wood, finish, colour and handles, so that we can create something that’s entirely unique to you. Our quality service ensures that no two vanity units are the same.

What’s more, our quality craftsmen are always on hand to provide guidance throughout the process, so you can rest assured you’re getting the best possible end product.

We can even adjust the design in order to fit around any obstacles within the room or to fit within a tight space which wouldn’t look right with an off the shelf vanity. So if you have some awkward pipes in your bathroom which have been boxed up or a unique alcove which otherwise wouldn’t be much use, we can design a vanity unit which is for the exact space it’s going in, making the most out of these spaces.

We help you choose the right wood for your vanity unit

We use three types of wood when it comes to building out vanity units – Pine (left), Tulip (middle) and Oak (right).

We recommend using Pine when the vanity unit is going to be completed with a painted finish. Pine can also be stained and and finished with a wax coating or by being lacquered.

We typically use Tulip wood for any vanity unit doors expecting a painted finish, as the natural properties of this particular type of wood are ideal for creating this component of the vanity unit.

Oak is one of the best types of wood to stain or to oil, so we would usually recommend this wood if you aren’t planning on having a painted unit and want to keep the natural wood style and pattern visible.

How we go about creating your bespoke vanity unit

Once all of your designs are in place then the manufacturing of your vanity unit can begin.

Made to measure

Firstly, the wood is cut to your requested length using a chop saw (below left), before it is then cut to the requested width using our table saw (below right).

The wood is then glued and clamped together, to form solid wood panels that make up the structure of your vanity unit, including the sides, the shelves and the flooring (shown below). At this time, the wood is also filled using a high-grade wood filler, on all naturally occuring knots in the wood. This helps to create a smooth finish to your bespoke vanity unit.

A solid structure with a smooth finish

We then leave the wood in tightened clamps for several hours, to allow the glue to properly set. Once the wood is out of the clamps, we can then get everything down to size before sanding down to create an even smoother panel (shown below).

Creating the front frame

The front frame of the vanity unit is biscuit jointed, screwed and glued together, then clamped to ensure everything sets in its proper place. Again, we use wood filler on the joints to make sure the completed unit has a consistently smooth finish.

Once the glue has dried and the front frame is out of the clamps, it too is sanded down using a palm sander to complete that all important smooth surface ahead of its final finish.

Once the components are sanded, they are then partially assembled, before the doors are created and fitted.

The building blocks of your bespoke vanity unit doors

Our vanity unit doors are made out of solid wood and they can include a panelled finish or a tongue and groove effect. The wood is put through our spindle moulder (shown below), to cut a groove in the depth of the wood, so that the chosen effect can be inserts into this and the door can be constructed, using biscuit joints screwed and glued together.

The finishing touches

Once all of the completed components are ready, we send them to our finishing unit.

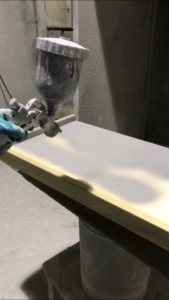

If you decide to opt for a painted finish vanity unit, it’s here that it will undergo a thorough process of being primed and sanded with 320 grit sandpaper, to ensure a smooth surface for the top coat. The unit is then then tacked to remove any dust, ready for the first layer of top coat to be sprayed on.

At this point, the paint is at 20% sheen level, but a satin finish also includes a hardener. Once again, the unit’s components are sanded with 320 grit sandpaper, before being tacked and sprayed with a second and final layer of top coat.

If you have ordered a bespoke vanity unit with an oiled finish, it’s here that it will be coated with Liberon Finishing Oil. The picture below shows a solid oak top receiving its first application.

The Countertop Is Added

We have options of both Marble and Oak countertops, which are the final touch to your vanity unit.

Marble countertops are one of the favourite options available and there are a variety of Marble finishes available. We work closely with you to ensure that a suitable countertop is used and that the sink and taps that you want to use will work with the countertop.

All marble countertops come at a 30mm thickness and are pre cut to fit sinks such as:

- Undercounter

- Inset

- Countertop

Your bespoke vanity unit is assembled ready to be delivered to your home

Once all the components have been finished to the highest of standards, the final assembly of your vanity unit takes place. This is where the front frame is attached to the sides, the doors are hung and the catches for the doors are installed.

Once fully assembled, your unit is given a final quality control check over by the company owner, before we personally deliver it to your home. From here, your chosen plumber can install the unit into its proper place.

It’s our job and our passion to make sure each and every vanity unit is built to the highest of standards and to the shape, size and style of your choosing. Our step by step process shows you just how much care and attention is given to the creation of our bespoke vanity units, so you can rest assured you’re investing in a quality vanity unit that’s just right for you.

If you have any further questions about our bespoke vanity units and how we would go about creating one for your home, please do not hesitate to get in touch with our friendly team.